EPA 2.0 DELIVERY PROPORTIONAL TO ADVANCE

Keeps the chemical mixture constant regardless of the forward speed variations

THE ADVANTAGES OF THE EPA 2.0 SYSTEM

EPA 2.0 KEEPS THE CHEMICAL MIXTURE CONSTANT (L/HA)

REGARDLESS OF THE FORWARD SPEED VARIATIONS DETECTED BY GPS.

Spraying quantity accuracy: decreasing the forward speed, the system automatically reduces the quantity delivered while increasing the forward speed, it increases the quantity delivered. This system avoids the product waste and assures treatment effectiveness, a great cost saving and a reduction on the environmental impact.

Easy programming is guaranteed as it is possible to save and manage up to 15 programmes, by entering the following operation parameters:

- - Tractor forward speed (km/h)

- - Row width (m)

- - Number of rows treated (n)

- - Mixture dose to be delivered (l/ha)

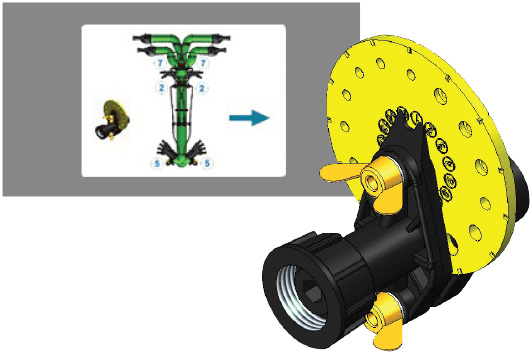

The EPA 2.0 system calculates the best hole in the yellow flow rate calibration disc to obtain the correct delivery.

- - The quantity of product per hectare to be distributed

- - The quantity of water to be introduced into the tank

- - The quantity of product to be put into the tank

- - Instant control of the mixture level

Any anomalies detected during the operation will be displayed on the EPA 2.0 screen.

Low quantity into the tank:

Upon reaching the reserve threshold, the EPA 2.0 shows the operator that the mixture level is low (the level indicator turns flashing red), notifying the operator to refill.”

In case the warning to refill is missed and the level reaches zero, delivery will stop so avoiding pump damage.

This message is also displayed when low pressure is detected (malfunction of the pump or the pressure regulation valve). If the operating pressure drops below the minimum value or exceeds the maximum value, the pressure value on the EPA 2.0 turns flashing red, indicating that the operation is performed at ± 30% of the set speed.

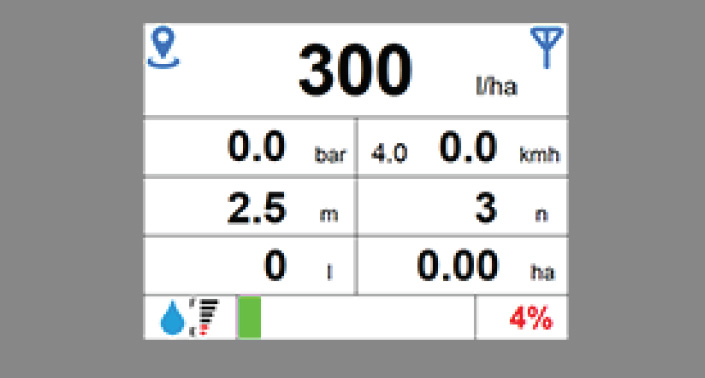

During the treatment the working data will be displayed on the EPA 2.0:

- Delivered dose (l/ha instant value)

- Working pressure (instant value)

- Forward speed (set value and instant value)

- Row width

- Number of rows treated

- Amount of mixture used

- Treated hectares

- Amount of residual mixture in the tank (in %)

If the distribution device is equipped with the hydraulic movement of the arms, these related movement keys are enabled for movement management of the three-way electro-hydraulic control unit.

EPA 2.0is fully compatible with the full range of CIMA’s low volume pneumatic sprayers

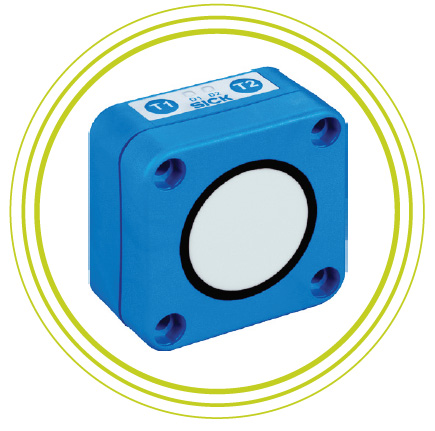

The ultrasonic sensors allow to detect the presence or absence of vegetation, ensuring the correct treatment at the beginning and at the end of the row, and interrupting the treatment in case of vegetation absence along the row.

The CIMA Easy Farm Kit is supplied complete with a management software for viewing the working data stored on the USB flash drive. During the treatment, EPA 2.0 records the working data in real time. Thanks to the CIMA Easy Farm Kit, at the end of the treatment or the day the operator can connect the USB flash drive to the company computer and view all the recorded working data.