The pneumatic Low Volume Venturi Air

Since 1974, easy, effective, unrivalled !

Using the unique Low Volume Venturi Air system by CIMA, you can save a huge quantity of water when spraying with our sprayers.

Discover more about the advantages against the High Volume.

The atomization

It is well- known that water is the needed carrier to effectively distribute the agricultural chemicals and obtain a complete and targeted coverage.

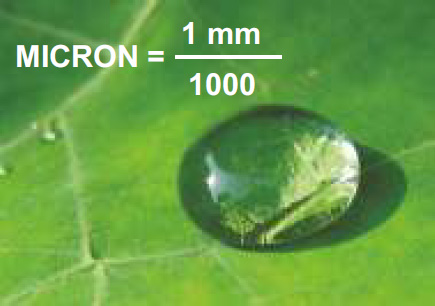

The size of the spray particles is measured in micron. One micron is one millimeter divided one thousand times (0,001 millimeter = 0,00006 inch).

"High Volume" system

The “traditional” sprayers use a diaphragm or piston pump to obtain a high water pressure to distribute the chemicals through one or more small diameter outlet/s. The use of a fan permits to “hold up” the water droplets by assisting the distribution of the chemicals over the vegetation. This system is conventionally called “High Volume”..

"Low Volume" sprayer

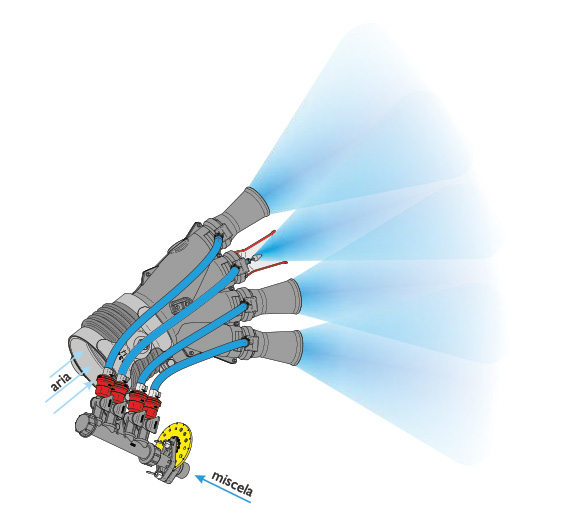

The CIMA pneumatic sprayers use a system based on the “Venturi tube”; a centrifugal fan generates an intense air flow that passes through the Venturi tube and exits through an adequate throat. The water is introduced, without pressure, into the throat of the Venturi and is sheared into extremely fine and uniform particles. The application of this principle is the essential and binding condition for the construction of pneumatic sprayers.

Let's compare the 2 methods!

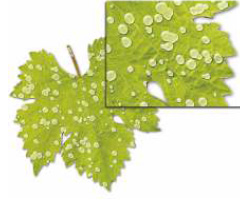

With the “High Volume”, the 85% of the droplets have a diameter of 300 / 500 microns. This size cannot be reduced, not even increasing the working pressure.

The distribution results rough and uneven, therefore of LESS EFFICACY.

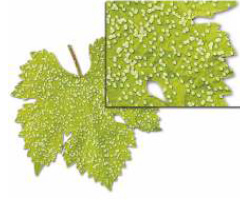

With the pneumatic Low Volume CIMA Venturi Air sprayers, the distribution generates a water fog with a smaller diameter for the 90% of droplets (usually 100 / 150 microns).

The distribution results precise and uniform, therefore of MORE EFFICACY.

The difference of the particle size is extremely important. At equal volume of the water used, it allows the pneumatic sprayers to do a distribution significantly larger than the “traditional” sprayers. In other words, CIMA pneumatic sprayers cover the same area of vegetation treated by the “high volume” sprayers but with much less water used, that is with a “low volume” of water.

Imagine to cover a given area with water droplets: it is obvious that smaller droplets will cover a bigger surface inside the given area.

From the volume of a 300 microns droplet we obtain 27 droplets of 100 microns. Even considering that the droplet diameter is the same of its imprint, the covered area moves from 0,07 mm² to 0,21 mm² , tripling.

However, if we consider the droplets flattening and the larger efficacy area of action coming from the volatility phenomena of the chemicals, and therefore the diffusion and saturation of the peripheral layer (the so-called “Fleming halo” whose thickness is estimated in about 100 microns), the covered area moves from 0.196 mm² to about 1.91 mm² , that means 10 times of increase roughly.

This is one of the main reason for the adoption of the small droplets, synonymous of “pneumatic low volume”.

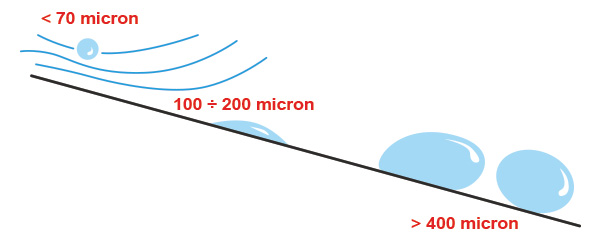

Furthermore, it is important to consider the droplets dynamic behaviour. Due to the surface tension and to the bigger volume, the bigger droplets (more than 400 microns) have a less adhesion and cause losses because of the great accumulation, of the deposit uneven, of the runoff onto the leaves and of the dripping onto the ground. Droplets too small (less than 70 microns) are very sensitive to the wind, the high temperature might cause their evaporation making them very small or even drying the solute chemical particle.

On the contrary, the 100 / 200 microns droplets have a better distribution and, carried by the air spray, penetrate into the vegetable interstices and create a more uniform coverage without dripping.

Regardless of the type of sprayer used, the quantity of chemical to distribuite per hectare remains unchanged, based on the crop to treat.

EQUAL AREA (1 HECTARE)

| SPRAYER USED | SPRAYING SYSTEM | CHEMICAL USED | WATER USED | CHEMICAL CONCENTRATION |

|---|---|---|---|---|

| Air blast sprayer | High Volume | 3 kg | 1000 litres | 1 TIME or NORMAL = 300 gr. X 100 lt. |

| Pneumatic sprayer | Low Volume | 3 kg | 333 litres | 3 TIMES = 900 gr X 100 lt. |

| Pneumatic sprayer | Low Volume | 3 kg | 200 litres | 5 TIMES = 1500 gr X 100 lt. |

| Pneumatic sprayer | Low Volume | 3 kg | 125 litres | 8 TIMES = 2400 gr X 100 lt. |

Go to the product brochure and compare the Low Volume to the High Volume